Laser Surface Velocimeter – Laser Doppler Measurement Systems

Product Types of Laser-Encoder Length Measurement Systems and Speed Measurement Systems

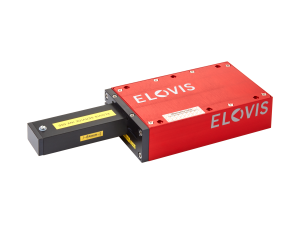

µSPEED‐PROBidirectional non-contact laser length measurement system for nearly any application and material movement as well as conveying processes.

|  |

µSPEED‐SMARTUnidirectional non-contact laser length measurement system for conveying processes with few stops. System is identical to μSPEED-PRO (see above), except for:

|  |

µSPEED‐SMART-ECOUnidirectional non-contact laser length measurement system with medium accuracy for conveying processes with few stops.

|  |

Technical data for the product range of laser-encoder length measurement systems and speed measurement systems

| µSPEED-PRO | µSPEED-SMART | µSPEED-SMART-ECO | |

| Direction Detection | non-contact | via external direction signal | via external direction signal |

| Measurement starting from V=0 | non-contact | optional | No |

| Material Presence | non-contact | optional | No |

| Accuracy (typ.) (2σ;L>10m/3σ;L>20m) | ± 0,05 % | ± 0,05 % | ± 0,3 % |

| Repeatability | ± 0,02 % of the measurement value (except SMART-ECO) | ||

| Sensor Type | Smart Sensor | Smart Sensor | Smart Sensor |

| Speed Measurement Range | 0 to ± 1.200 m/min 0-20 m/s | 1 to ± 6.000 m/min 0,02-100 m/s | 1 to ± 6.000 m/min 0,02-100 m/s |

| Stand-off Distance (Tolerances) | 115±5 (±20) mm | 120±5 (±20) mm 240±10 (±40) mm | 120±5 (±20) mm 240±10 (±40) mm |

| Interfaces | 1 x RS-485 or RS-232 alternatively to I/Os: RS-422, RS-485 | ||

| I/Os | Quadrature Output 1 to 100.000 (depending on maximum speed) pls/m Input: Start, Gate, Direction, Laser Interlock Output: Status | ||

| I/O Type | RS‐422 Gauge Laser Interlock (single, 24V) | ||

| Available Data | speed, length, signal quality, status, laser interlock, valid measurement material present (only PRO) | ||

| Fieldbus | Profibus, CANopen, DeviceNet, CC‐Link Ethernet‐IP, Profinet‐IO, Modbus‐RTU Bluetooth (All Fieldbus optional) | ||

| Class of Protection | Sensor Head: IP67 Controller/MID-COUNTER: Front: IP51; Back: IP20 | ||

| Dimensions (LxWxH) | Sensor Head: 154x94x39 mm | ||

| Weight | Sensor Head: 0,9 kg | ||

| Power Supply | 24 VDC (18 V to 30 V) | ||

| Operating Unit | optional | ||

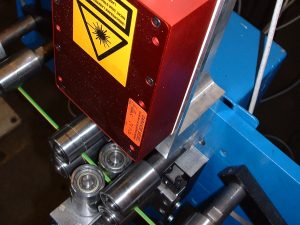

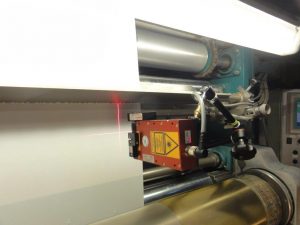

| Laser Data | 25 mW, 780 nm (Laser Class 3B) | ||

| Ambient Temperature/Humidity | 5 to 55°C ‐ not condensing beyond temperature range – external cooling / heating required | ||

Accessories for laser encoder-length measurement systems and speed measurement systems

Standard Interface |

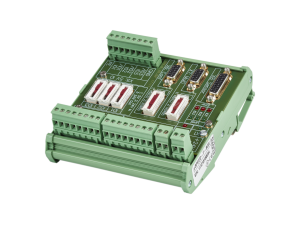

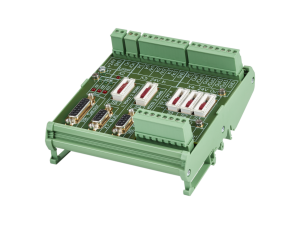

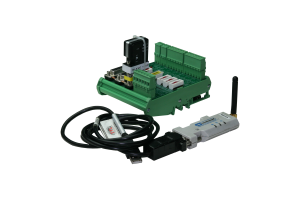

Terminal-Box µSPEED-T-BOX | The μSPEED-T-Box terminal unit enables easy and safe connection and supply of the μSPEED-SMART, μSPEED-SMART-ECO and μSPEED-PRO sensors. The top-hat rail module is intended for installation in a control cabinet |

Sensor Cable |

Shielded Cables µSPEED-C10, C25, C50 | Sensor cables for connecting the µSPEED sensors with the µSPEED-T-Box in lengths between 10 and 50 m (greater lengths only on demand) |  |

Display and Control Units |

Length Counter, Speed Display µSPEED-CNT-M, µSPEED-TACHO-M | Simple length counter or tachometer to display the μSPEED length & speed measurement values. 6-digit display, 14 mm character height |  |

Control Unit µSPEED-CONTROLLER | Display and control unit for the μSPEED sensors among other things provide the following functionality:

| |

MID-Counter (calibrated) µSPEED-MID-COUNTER | Counter with calibration license, which can be used for length measurement in conjunction with the optical laser sensors μSPEED-SMART and μSPEED-PRO or alternatively with a rotary pulse generator. Click here for more infos! | |

Display Unit for Length and Speed µSPEED-CNT/TACHO | µSPEED-CNT/TACHO beinhaltet einen Längenzähler, eine Geschwindigkeitsanzeige sowie einen Laser-Ein/Aus Schlüsselschalter. Die Anzeigeeinheit ist als Beistelleinheit für den Stand-Alone Betrieb von µSPEED Sensoren konzipiert. Über eine RS 232 Schnittstelle kann die Datenausgabe an einen PC erfolgen. | |

Serial Large Display µSPEED-DIS | μSPEED-DIS is used to read μSPEED measurement values from a distance. The large display is equipped with 6 digits as standard, but can optionally be set up as 4 or 8-digit 7-segment display. Character height: 57 mm |  |

Mobile Equipment |

Software |

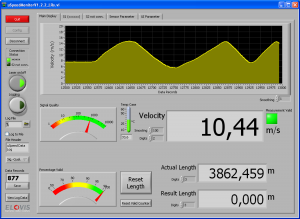

PC Software µSPEED-CMS | The configuration and monitoring software µSPEED-CMS is used for operating µSPEED, as well as displaying and storing µSPEED measurement values on a pc, laptop or tablet. The CMS software is mainly used at portable measurements |

Fieldbus and Communication Modules |

Profibus-DP, ProfiNet-RT, Ethernet-IP µSPEED-PB, µSPEED-PN, µSPEED-EN | Standard Bus Interface Module with the following output: Length (in m) , Speed (in m/s), Status Signal (valid/invalid) |

Protection Casing |

Casing for air cooling µSPEED-HSEe | The casing μSPEED-HSEe made of stainless steel is used to protect the sensor head from contamination and from unsuitable ambient temperatures. The HSEe must be supplied with suitable purging air. | |

Casing for air cooling and water cooling µSPEED-HSEw | The casing μSPEED-HSEw is used to protect the sensor head from contamination and from unsuitable ambient temperatures. The HSEw must be supplied with suitable purging air. It is designed for higher ambient temperatures due to the additional connection for water cooling. The HSEw contains two heat exchanger plates. | |

Heat Exchanger Plates µSPEED-HE | Heat exchanger plates with 2 cooling water flange connections can be mounted on one or both sides of the sensor head. The water-rinsed heat exchanger plates allow the use of the sensor in a warm measuring environment. | |

Quick Cange Protective Glass µSPEED-QCW | The μSPEED-QCW Quick Change Protective Glass is designed for use in harsh environments with heavily polluted ambient air. The QCW allows the replacement of the protective glass in seconds and allows the actual cleaning of the glass can be operated detached from the sensor. | |

Air Purge µSPEED-FAN

| The air purge μSPEED-FAN is used to supply μSPEED HSE casings with purge air. Depending on the application, the purging air can be used for heating, for cooling the sensor or merely for avoiding contamination of the sensor optics. HSE and FAN are connected with an air hose. |

Sensor Mounting Plate |

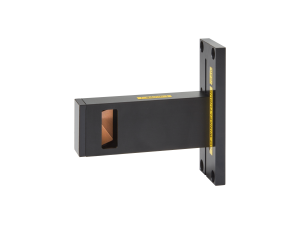

Mounting Plate with swivel/slot hole element µSPEED-MP | μSPEED-MP is set up via rotary element, which allows an angular adjustment of the sensor in the material movement direction by +/- 80 °. Slotted holes on the rotary element allow a distance adjustment of the sensor head |

Height Adjustment Unit |

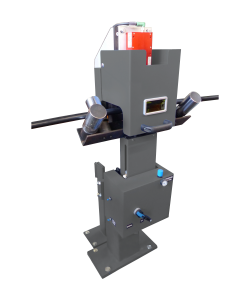

Cable Guidance with Stand |

Laser Protection Equipment |

Lable Printer |

Radio Data Transmissions |

Battery Module for self-sufficient system operation |

Laser-Encoder Lenght Measurement Systems and Speed Measurement Systems

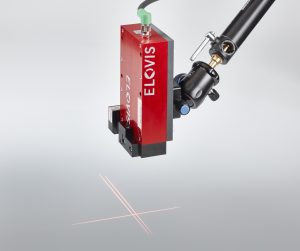

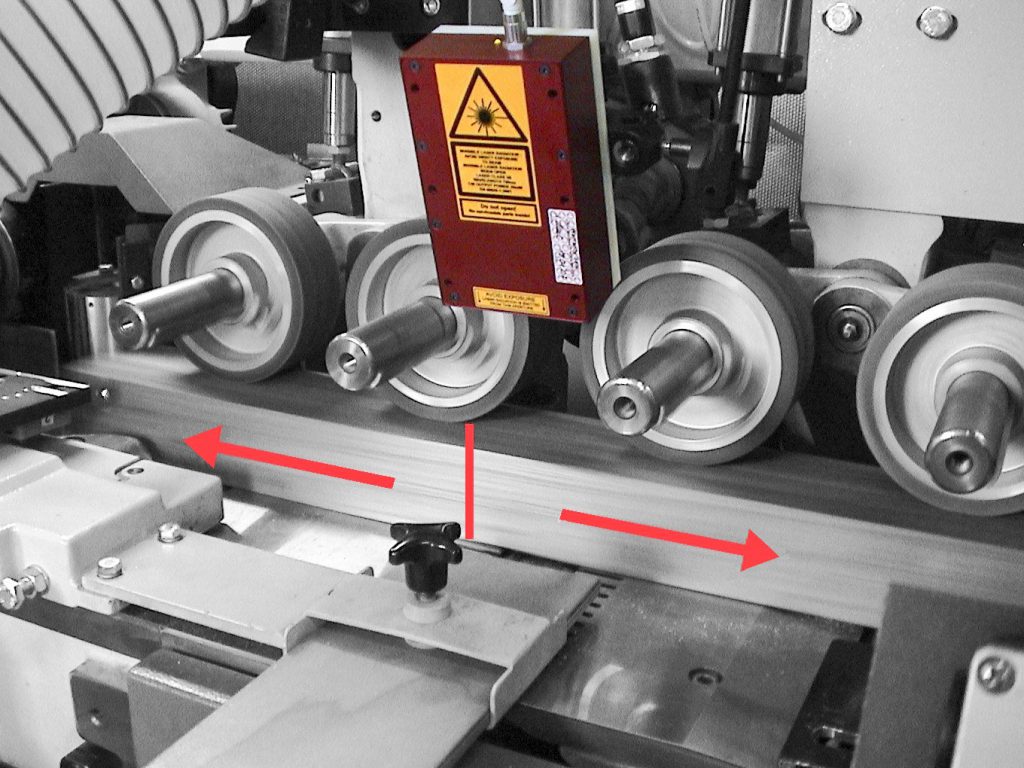

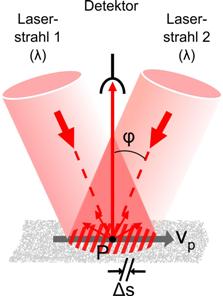

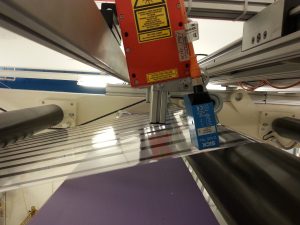

By means of two laser beams, a bar pattern is generated on the material measurement surface. The movement of the surface of the measurement material modulates the intensity of the backscattered light into the detector, the frequency of the brightness modulation being directly proportional to the speed of the medium and to the Doppler frequency. The scattered light is converted into an electrical signal via a photodetector and fed via an analog / digital converter to a processor. The processor determines the current speed and path length from the digitized signal. The use of marks or scales on the test object is not necessary. The procedure is known by the name of “Laser Surface Velocimeter – Laser Doppler Measurement System”.

Videos for the product range of laser-encoder length measurement systems and speed measurement systems

Laser-Encoder Length Measurement Systems and Speed Measurement Systems Product Tutorial |  |

Laser-Encoder Length Measurement Systems and Speed Measurement Systems Product Explanation and Application Overview |  |

Length Measurement in Fabric Production – µSPEED Laser-Encoder Length Measurement Systems and Speed Measurement Systems Measurement at the production output with a portable µSPEED system |  |

Repeat Length Measurement – µSPEED-RL Laser Encoder Length Measurement Systems and Speed Measurement Systems Laser-precise measurement of repeat mark distances in a film printing machine |  |

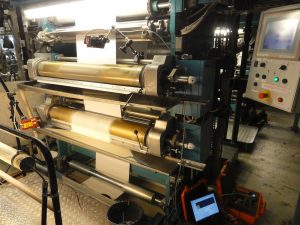

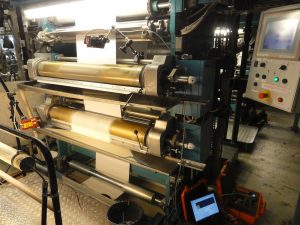

Differential Speed Measurement in Foil Coating Production – µSPEED Laser Encoder Length Measurement Systems and Speed Measurement Systems Measurement on a web and parallel on the coating roller with μSPEED parallel systems |  |

Paper-Roll Cutter Counter Calibration – µSPEED Laser Encoder Length Measurement Systems and Speed Measurement Systems Calibrating the length counter of a winder with a portable μSPEED sensor |  |

Tenter Frame Shrinkage Measurement – µSPEED Laser Encoder Length Measurement Systems and Speed Measurement Systems Differential measurement in the goods infeed as well as in the goods outfeed for the determination of the goods advance |  |

Wire Length Measurement – µSPEED Laser Encoder Length Measurement Systems and Speed Measurement Systems Length measurement in bare-wire production with μSPEED laser system |  |

Steel Rope Length Measurement – µSPEED Laser Encoder Length Measurement Systems and Speed Measurement Systems Testing the measurement accuracy of a system counter for ropes with portable μSPEED laser sensors |  |

Textile Fabric Inspection Length Measurement – µSPEED Laser Encoder Length Measurement Systems and Speed Measurement Systems Length measurement machine for textiles is calibrated without contact with μSPEED |  |

Nonwoven Length Measurement – µSPEED Laser Encoder Length Measurement Systems and Speed Measurement Systems Length measurement in a nonwoven fabric production machine without contact with μSPEED laser Doppler system |  |

Certified length measurement – fabric inspection – µSPEED- MID 2014/32/EU Laser Encoder Length Measurement Systems and Speed Measurement Systems Certified, non-contact length measurement with µSPEED system in a fabric inspection machine |  |

Downloads for the product range of laser encoder-length measurement systems and speed measurement systems

Product Information – µSPEED Length & Speed Measurement

|

| µSPEED – Product Overview |

APPLICATIONS

Roll Length/Coil Length

Is your billing based on correct length values? Are all materials measured with same accuracy? Or do you risk len...

Cut-to-length Control

Do you avoid length additions or do you deliver excess length just to be safe? Do you have the strict requirement to ...

MID certified Length Measurement

If goods are sold in Europe by length or area, they generally must be measured with "MID-certified" calibrated length...

More

Portable/Mobile Length Measurement, Encoder Calibration, Discrete Part Length Measurement, Speed

Measurement, Meas...

Portable/Mobile Length Measurement

Where do you lose lengths during the production process? Where does waste or rejects occur? Does material shrinkage o...

Encoder Calibration

Do all system counters work with the same accuracy across the production spectrum? Which method do you use to check t...

Discrete Part Length Measurement

Are you interrupting your production or reducing the throughput speed to check lengths manually? Sample test costs pr...

Speed

Measurement

Should the speed of moving web and parts be accurately recorded in order to monitor, control and regulate machines? M...

Measurement of Differential

Speed

Record differential speed between web, cylinder, conveyor belt or support screen in order to monitor, control and reg...

APPLICATION EXAMPLES

Length Measurement of transparent Foil

Precise length measurement on transparent film and foil for the food indutry and optical films. Length measurement on...

Length Measurement of Paper

Accurate length measurement of paper, tissue, packaging material regardless of grammage - also as a basis for square ...

Length Measurement of Cable and Flat Cable

Length measurement of cable and flat cable is done in many different applications. For example, already in production...

Length Measurement of Nonwovens

Length measurement of nonwoven, felt and material with high thickness variance and different grammages with consisten...

Length Measurement of Separator Film

Battery separator foil must not show any holes, folds, kinks or damage, otherwise this may result in considerable dam...

Cutting Control in Pipe/Profile Extrusion

When sawing and cutting extruded materials, such as pipes, hoses and profiles, a slip-free length measurement is esse...

Carpet Cutting Control

Hardly any material is more diverse than carpet and therefore difficult to measure in length. Carpeted floor can be 2...

Roll Cutter for Roof Membranes

Due to the large number of different measuring surfaces, the CTL length cutting of sales rolls of roofing membranes, ...

Cutting Control on Cables and Wire

Cable and wire are rewound and cut at high speed. Due to the high raw material prices, the ordered sales lengths must...

CAMPEN off-line Slitters Rewinders

CAMPEN Machinery A/S off-line slitter and rewinders from Denmark are customer specific machines for rewinding and sli...

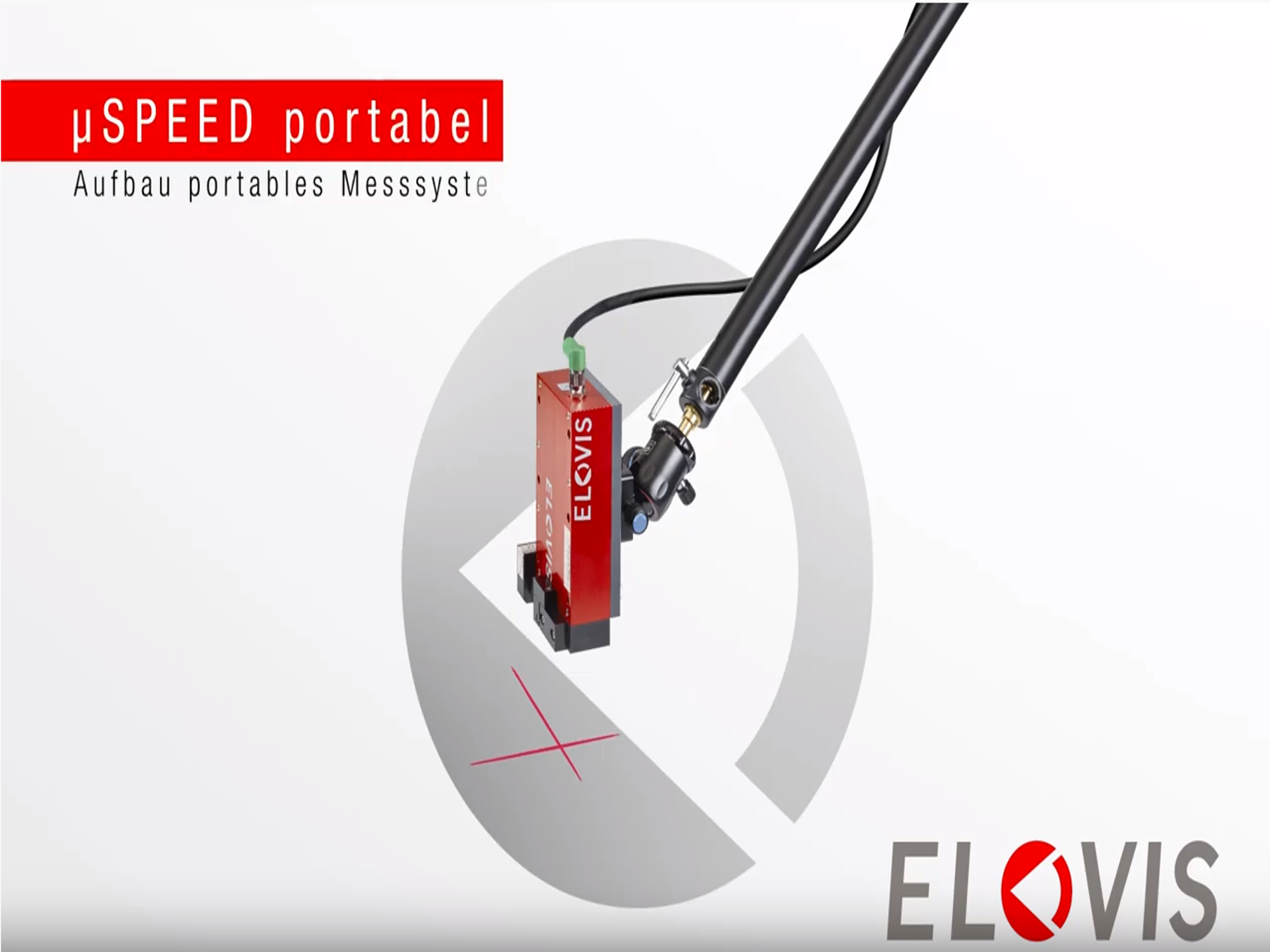

Tripod-held Length Measurement System

Comparing the preparatory effort to a hand-held measurement system, only much safer, ELOVIS length measurement system...

Cylinder Speed, Roller Speed

Cylinder speeds and roller speeds often decide on the material quality and the degree of utilization of machines. Dri...

Differential V between Drive and Material

Machine drives and material should be moved with the lowest possible differential speed. Ensuring this is not easy an...

V-Measurement through portable Sensor

Frequently, machine operators are interested in the process analysis for goods speed and speeds of machine components...

Length Measurement of Umbilical, Submarine Cables and Ropes

Wet and dirty umbilical / submarine cables as well as rough stranded ropes and cables can best be measured with non-c...

Length Measurement of Ropes in the Braiding Machine

Measurement of rope lengths in the stranding machine by means of non-contact laser-encoders. Accurate measurement des...