Accurate Measurement of Roll Length even at high Speed

Non-contact measurement of roll length and coil length – typical roll and spool measurement materials:

- Film, Foil, Tarpaulins, Membranes,

- Cable, Wire, Rope

- Paper, Cardboard, Tissue, …

- Textiles, Carpets, Nonwoven, Fabrics

- Web, Sheets, Foils of Metal

- Profiles, Tubes, Hoses, Strands

- Packaging Material of Plastic, Paper, …

non-contact measurement of roll length and coil length – machines with measurement problems:

- Winders, Winding Machines, Rewinding Machines

- Slitting Machines, Lengthwise Cutter

- Roll Cutting Machines, Cross Cutter

- Fabric Inspection Machine

- Calendering Machines

- Laminators

Application Examples

Length Measurement of transparent Foil

Precise length measurement on transparent film and foil for the food indutry and optical films. Length measurement on...

Length Measurement of Film

Non-contact length measurement of strongly reflective, mirrorlike film and foil for the food indutry and optical film...

Length Measurement of Paper

Accurate length measurement of paper, tissue, packaging material regardless of grammage - also as a basis for square ...

Length Measurement of Nonwovens

Length measurement of nonwoven, felt and material with high thickness variance and different grammages with consisten...

Length Measurement of Separator Film

Battery separator foil must not show any holes, folds, kinks or damage, otherwise this may result in considerable dam...

Length Measurement of Cable and Flat Cable

Length measurement of cable and flat cable is done in many different applications. For example, already in production...

Length Measurement of Wire

The length measurement of wire is carried out in different applications. For example, already in production in drawin...

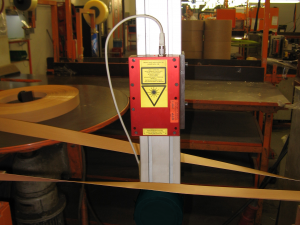

Length measurement of edge-adhesive tape / decorative paper

Edge-adhesive tape and decorative paper are produced in a large variety of decor and structures in large batches. How...

Length of Steel Sheets in Refinement Facilities

The length measurement of a steel sheet with oiled surface, over embraced rollers is possible only with limited accur...

Length of steel cables and hot wire

Steel ropes and hot wire are in long lengths and at high speeds correctly cut to length. In both cases, contact measu...

Length Measurement of Umbilical, Submarine Cables and Ropes

Wet and dirty umbilical / submarine cables as well as rough stranded ropes and cables can best be measured with non-c...

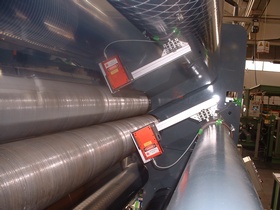

Length Measurement of Ropes in the Braiding Machine

Measurement of rope lengths in the stranding machine by means of non-contact laser-encoders. Accurate measurement des...

Matching Products and Services

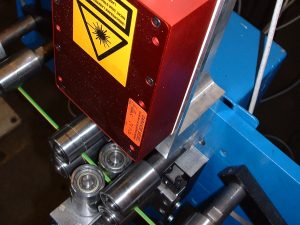

Laser-Encoder

Length & Speed Measurement Systems

- Non-contact length and speed measurement, optically by laser

- Length and speed free of slippage, maintenance-free, permanently calibrated and accurately measured

- The Laser-Encoder replaces tactile measurement via impeller, wheel, measurement roller, or machine drive

- Measurement of agitated surfaces via laser-doppler surface velocimeter

ELOVIS Services

ELOVIS offers the following services in this area:

- Consulting on the subject of length and speed measurement

- Measurement and calibration services

- Help with length complaints from your customers

- OEM sensor developments in the field of length and speed measurement